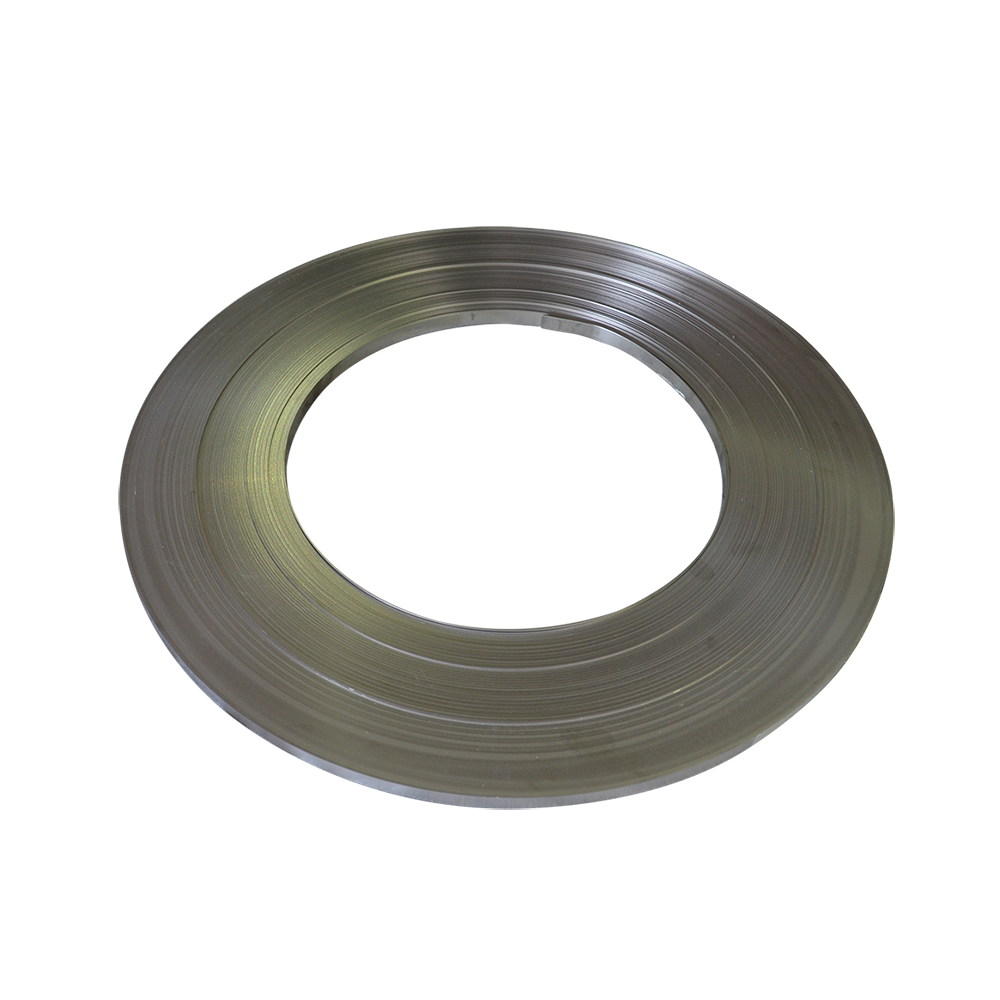

QUALITY SUBSTRATE MATERIAL

Our conductor bar is pure titanium and its chemical composition complies with ASTM B265 Grade I. It can have a life expectancy of 50 years or more.

|

Element |

Grade I |

|

Iron (Fe) |

0.20% max. |

|

Carbon (C) |

0.08% max. |

|

Nitrogen (N) |

0.03% max. |

|

Hydrogen (H) |

0.015% max. |

|

Oxygen (O) |

0.18% max. |

|

Titanium (Ti) |

Remainder |

DIMENSIONAL STABILITY

Thanks to its stable chemical composition, this aerospace material is mechanically strong as well as ductile. It is easy to form and install in applications where available space is restricted.

|

Technical Measurement |

Performance |

| Coefficient of Thermal Expansion |

8.7 × 10-5 / K-1 (4.8 × 10-6 / in / in / ºK) |

|

Thermal Conductivity @ 20ºC |

15.6 W/mºK (9.0 BTU/hr·ft2·°F) |

|

Electrical Resistivity @ 20ºC |

56 × 10-6 Ω·cm (22 × 10-6 Ω·in) |

|

Modules of Elasticity (Min.) |

105 GPa (14,900,000 PSI) |

|

Tensile Strength (Min.) |

245 MPa (35,000 PSI) |

|

Yield Strength (Min.) |

175 MPa (25,000 PSI) |

|

Elongation (Min.) |

24% |

PRACTICAL APPLICATION

Our titanium conductor bar is highly resistant to corrosion in various environments. It can be utilized in sandy soil, coke, seawater, brackish water and other complex environments with the presence of oxygen evolution, chlorine evolution or a mixture of the two.