Quality Substrate Material

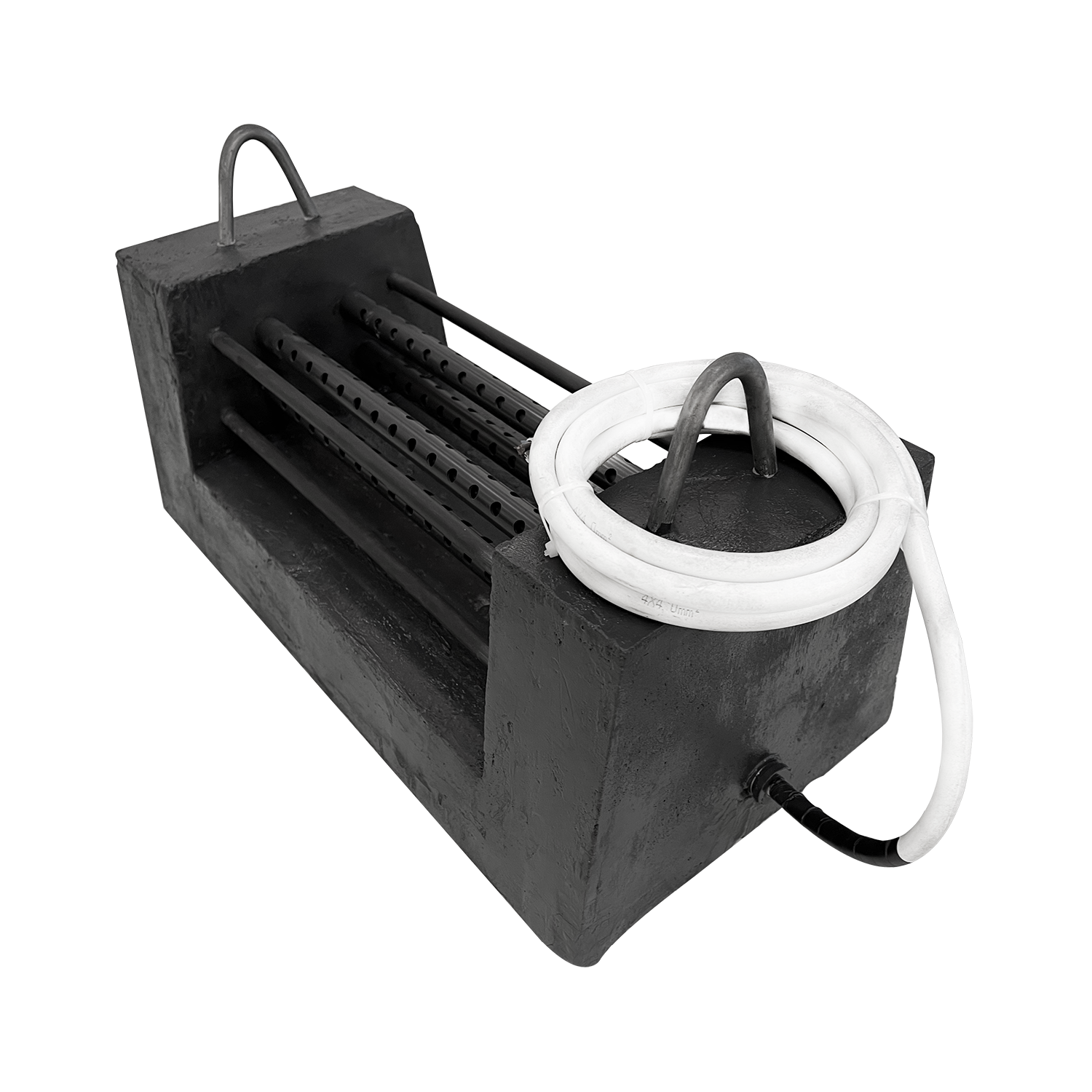

Our MMO tubular anode is manufactured from high-tensile seamless titanium tube, which meets ASTM B338 Grade 1 standards.

|

Element |

Grade I |

Grade II |

|

Iron (Fe) |

0.20% max. |

0.30% max. |

|

Carbon (C) |

0.08% max. |

0.08% max. |

|

Nitrogen (N) |

0.03% max. |

0.03% max. |

|

Hydrogen (H) |

0.015% max. |

0.015% max. |

|

Oxygen (O) |

0.18% max. |

0.25% max. |

|

Single Impurity (Each) |

0.10% max. |

0.10% max. |

|

Other Impurities (Total) |

0.40% max. |

0.40% max. |

|

Titanium (Ti) |

Remainder |

Remainder |

Noble Metal Oxide Coating

Whether operating in soil, fresh water, seawater or mud, mixed metal oxide coatings demonstrate high chemical stability, even in environments with a low pH value. The Ir-Ru mixed metal oxide catalyst is recommended for brackish and seawater. Based upon accelerated life testing, conducted by an independent laboratory, our MMO coating has been proven to have an increased life expectancy when compared with other similar products on the market. Differing coating thickness and different noble metal oxide ratios are available on request.

|

Technical Measurement |

Performance |

| Coating Element |

IrO2, RuO2 |

|

Coating Thickness |

5~10 μm |

|

Coating Uniformity |

85% min. |

|

Working Environment |

Mud, Concrete, Seawater |

Low Electrical Resistance

The MMO anode has an extremely low consumption rate, measured in milligrams per ampere-year. The dimensions remain nearly unchanged throughout the design life of the anode, providing a consistently low resistance.

Low Maintenance Cost

MMO tubular anodes are a high performance anode specifically designed for harsh environments and areas where conventional installations and replacements would be economically or logistically restricted. When compared to other anode types, it can save up to 15%-35% of installation costs.

Wide Cable Selection

PVDF, HMWPE, HALAR, XLPE, PVC or KYNAR are all optional. We recommend dual-insulated cable(such as PVDF/HMWPE) for use in ground beds with high chloride concentration. While HMWPE is an economical choice for shallow vertical and horizontal surface beds with no chloride presence.

Long Working Life

The design life of the anode varies with the operating current supplied for the various applications.